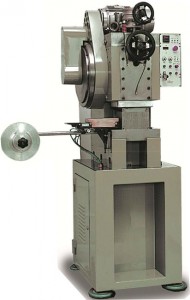

- An automatic 5 Ton press which automatically cuts and stamps (with your hallmark) end clips, quality tags or other blanks from a strip which is automatically fed into the machine at various pitches. Different shapes and sizes are obtained by simply changing the die block and inserting a new one. It is also able to hammer and calibrate different chains simply by changing tool sets on the unit. The length of the press stroke is adjustable to meet any production need. The unit comes complete with a programmable piece counter stopping the unit once reaching the number of pieces required.

-

Technical features Press power 5 Tons Press stroke (max) 12 mm Strip width (max.) 40 mm Feeding pitch (max.) 28 mm Press speed 600 strokes/min Technical data Voltage (single phase) 230 V 50/60 Hz Power 1 kW Compressed air 1 lt./min (dry) at 6 bar Dimensions 65 x 42 x 170(h) cm – 180 kg Packing 188 x 64 x 68 (h) cm – 210 kg - Download Technical File

An automatic 5 Ton press which automatically cuts and stamps (with your hallmark) end clips, quality tags or other blanks from a strip which is automatically fed into the machine at various pitches.

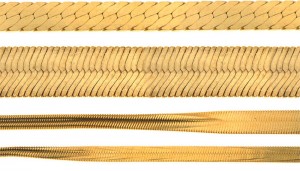

A fully automatic press for the hammering of compacted (and non) chains. This 30 Ton high precision hammering press is extremely versatile and high precise, leaving no room for error with its micrometric accuracy level. A simple but effective traction system will only pull the chain through the stamping blocks only when the blocks are open and not blocking the chain. This of course avoids any excess and uncontrolled stretching of the chain. The toggle system based hammering mechanism ensures total and controlled power at every stroke with a minimum force on the internal mechanisms thus reducing wear and maintaining high accuracy throughout the machines life. Tool change is fast and easy thanks to the rapid blocking system. A very silent machine, it is provided with a pneumatic clutch and brake system, and its own forced lubrication system. Technical features Press power 30 Ton Production speed up to 600 strokes/min Useful stroke 116 to 126 mm Technical data Voltage (threephase) 400 V 50 Hz Power 3 kW Compressed air 3 lt./min (dry) at 6 bar Dimensions 100 x 90 x 200(h) cm – 1,250 kg packing 122 x 122 x 226(h) cm – 1,400 kg

The PB2 automatic hammering press is more than just a hammering unit. Thanks to the unique design, and conception, the machine actually moulds the piece it is processing to a new form and internal structure. This gives the hammered material a perfectly uniform structure. The hammering process has an accuracy of 0.01 mm thus greatly improving production efficiency, in that less material will have to be removed in surfacing procedures. The perfect finish of the hammered surface and the absence of lateral trimmings allow to reduce process time to an absolute minimum.Technical features Press power 150 Tons Feed pitch up to 10 mm Process width 25 mm Production speed up to 400 strokes per minute Technical data Voltage supply (three phase) 400 V AC 50 Hz Power supply 16 kW Air supply 2 l for each work cycle at 6 bar Water supply 300 l/h at 5 bar and 16 – 24 °C Dimensions 190 x 145 x 180(h) cm – 2,200 kg packing press 137 x 139 x 207(h) cm – 2215 kg control panel 153 x 75 x 124(h) cm – 301 kg

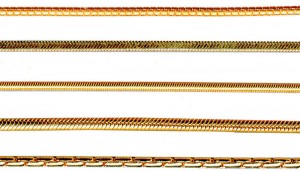

Extremely fast and precise hammering unit specially designed for calibrating round chains. Very silent machine meeting all safety and environmental standards for full future production requirements. Comes complete with an internal water cooling circuit so as to guarantee a constant temperature during the hammering process thus guaranteeing centesimal precision.

Technical features Rotation speed 500 rpm Production speed 5 m/min Chain dimensions Ø 0.60 to 3.00 mm Hammering power up to 900 kg. Technical data Voltage 230 V Power 1 kW Cooling water 120 l/h max. at 18°C max. Compressed air 1 l/h at 6 bar Dimensions 100 x 78 x 150 (h)cm – 203 kg Packing 89 x 69 x 131(h) cm – 263 kg